The following is an aerostructural shape optimization case for the UAV propeller in hover. The baseline design is an untwisted, untapered NACA 0012 propeller blade. The flow is solved using the DARhoSimpleFoam CFD solver and the structure is solved using an open-source FEM solver TACS. The load and displacement transfer is computed using FUNtoFEM. The aerostructural coupling is implemented in the OpenMDAO/Mphys framework.

Case: Propeller aerostructural optimization Geometry: NACA 0012 UAV Propeller Objective function: Shaft Power Coefficient Design variables: 6 twist variables, 72 shape variables, 6 chord variables, rotation speed Constraints: Thrust coefficient, propeller thickness, propeller spanwise curvature, leading edge, and mass RPM: 5000 Reynolds number: 180 thousand Mesh cells: ~1.5 million Solver: DARhoSimpleFoam

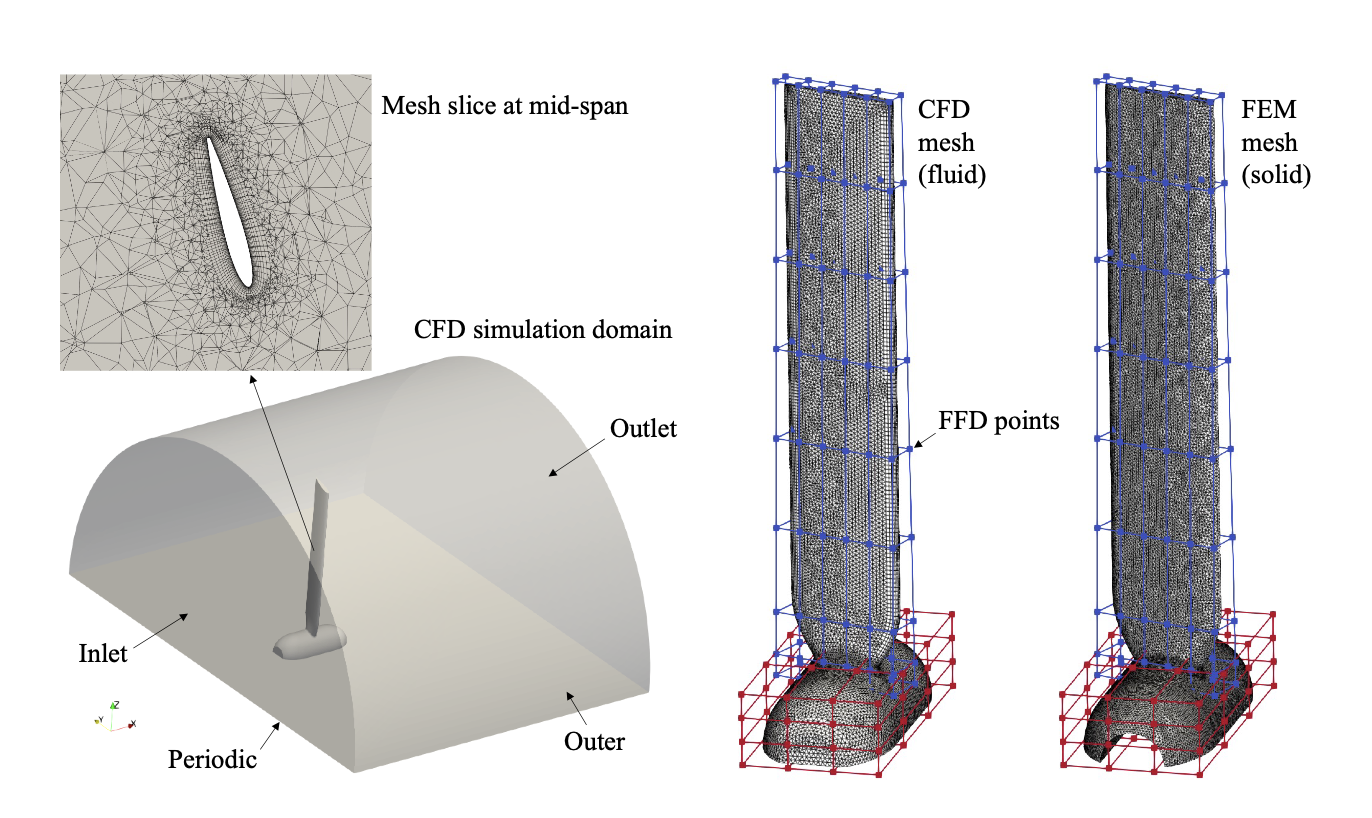

Figure 1. Simulation domain, propeller meshes, and FFD points. The blue and red squares are the FFD points. Only the blue FFD points move during the optimization.

To run this case, first download tutorials and untar it. Then go to tutorials-main/UAV_Prop and run the “preProcessing.sh” script to generate the mesh:

./preProcessing.sh

Then, use the code below to run the optimization using 144 CPU cores:

mpirun -np 144 python runScript_AeroStruct.py 2>&1 | tee logOpt.txt

The case in this tutorial ran for 42 iterations, and the optimality dropped by one order of magnitude. In total, we saw an 18.3% reduction in power, while the thrust, mass, and stress constraints were met.

Figure 2. Comparison of the baseline and optimized designs for case where twist, shape, and chord are design variables.