Note: We recommend going through the tutorial in Get started before running this case.

The following is an aerodynamic shape optimization case for the NREL6 wind turbine blades.

Case: Wind turbine aerodynamic optimization Geometry: NREL6 Objective function: Torque Design variables: 100 FFD points moving in the x and y directions Constraints: None Inlet velocity: 7 m/s Rotation speed: 7.5 rad/s Mesh cells: 800 K Solver: DATurboFoam

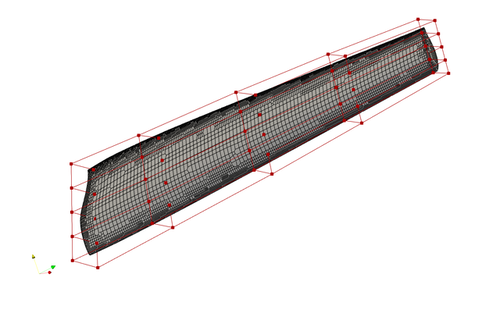

Fig. 1. Mesh and FFD points for the NREL6 case

To run this case, first download tutorials and untar it. Then go to tutorials-main/NREL6_Wind_Turbine and run the “preProcessing.sh” script to generate the mesh:

./preProcessing.sh

We recommend running this case on an HPC system with 80 CPU cores:

mpirun -np 80 python runScript.py 2>&1 | tee logOpt.txt

The case ran for 82 major iterations and took about 33 hours using HPC with 72 cores. According to “opt_snopt_summary.txt”, the initial torque is 6.7699821E+02 and the optimized torque is 1.2347349E+03 with a percentage increase of 82%. The evolution of pressure and shape during the optimization is as follows.